China Zhongwang Holdings Limited (“

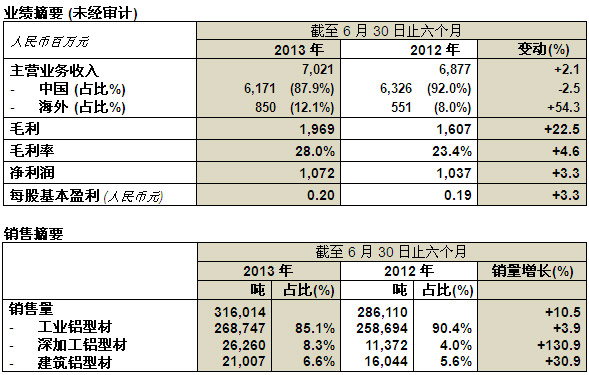

China Zhongwang” or “the Company”, together with its subsidiaries “the Group”, stock code: 01333), the second largest industrial aluminium extrusion product developer and manufacturer in the world and the biggest one in Asia and China, announced the unaudited results for the six months ended 30 June 2013 (the “review period”). The Group delivered steady business growth in the first half of 2013. Revenue and profit attributable to shareholders rose 2.1% and 3.3% respectively year-on-year to approximately RMB7.02 billion and RMB1.07 billion respectively. Gross profit margin rose to 28.0%, an increase of 4.6 percentage points compared with the same period last year. As the newly built further fabrication center commenced its production, high value-added further fabricated products fueled export business growth. Export sales volume surged by 119.3% to approximately 30,000 tonnes, while sales amount grew by 54.3% to approximately RMB850 million.

The Group continued to focus its resources on tapping opportunities in the China market, while assigning a supplementary role to the export market. During the review period, China market remained the Group’s major source of revenue. It recorded RMB6.17 billion from PRC sales, representing 87.9% of total sales. Total sales volume of aluminium extrusion products was 316,000 tonnes, representing a 10.5% growth year-on-year.

Mr. Lu Changqing, Executive Director and Vice President of China Zhongwang, said, “During the first half of 2013, China’s economic growth slowed down as the nation shifted its effort to realign its industrial structure. Despite the economic headwinds, the Group has actively enhanced its competitiveness as well as the technology level of its product and equipment, while continuing to pursue R&D breakthroughs. On expansion of the three core businesses, we have strengthened the foundation of the industrial aluminium extrusion business and extended its reach along the industry chain to cover high value-added industrial aluminium further fabricated products. In addition, we have steadily advanced the development of the high-end aluminium flat rolled product business, establishing an operational model to achieve sustainable business growth.”

Industrial aluminium extrusion–enhance capacity to boost efficiency

Since 2011, the Group has introduced 18 large-tonnage extrusion presses of 75MN or above. As of 30 June, 2013, it operated 87 extrusion lines with an annual production capacity of over 900,000 tonnes. 21 large-tonnage extrusion presses are 75MN or above, four of which are the world’s most advanced 125MN presses. In the second half of this year, the Group will speed up the process of installation and trial run for the remaining six extrusion presses. In addition, the Group ordered two 225MN large-tonnage extrusion presses with deliveries scheduled in 2014. These advanced presses will give a new impetus to the Group’s industrial aluminium business when they are put in place.

Further fabrication business–develop new products

The Group has actively been developing further fabrication business by extending its reach along the industry chain. During the review period, the sales volume of industrial aluminium extrusion further fabricated products increased substantially by 130.9% year-on-year to 26,000 tonnes. Sales rose by 67.2% year-on-year to RMB730 million.

Capitalizing on the opportunities from the light-weight development trend of the transportation sector, the Group continued to strengthen its technological level. During the review period, it successfully developed high-tech aluminium further fabricated products such as all-aluminium fire trucks, semi-trailers and high-speed rail carriages. With the further fabrication centre putting into operation, the Group has created a new growth engine in 2013.

Aluminum flat rolled product business–technology and talent already in place

During the review period, the Group made steady progress in the phase one construction of its aluminum flat rolled product project, with plans to manufacture high precision aluminum plate, sheet and foil products. Preliminary construction work is now in full swing for the Group’s production base which is located in Tianjin Wuqing Auto Parts Industrial Park. The aluminum flat rolled product manufacturing equipment ordered from Germany and the U.S. is scheduled for delivery in phases starting the end of this year. Mr. Lu added, “The Group has been recruiting overseas technology talents to join the team and has already hired a few dozens of elite engineers from overseas. Leveraging on our strengths in technology and talent, client base, as well as solid financial position, the Group will press ahead aluminium flat rolled business in full gear.”

Technology innovation breakthrough and industry-ready talents nurturing

The Group captured opportunities in the high-end segment of the aluminium extrusion industry by continued R&D investment and nurturing expertise. During the review period, the Group commenced a R&D project called "7075 Extrusion Billets for Aviation Use." As aviation and aerospace sectors impose stringent requirements on specifications, properties and qualities of aluminium extrusion products, the project represents the Group’s new technological milestone in the production of high-end products. The Group also partnered with a number of reputable domestic academic institutions to nurture industry-ready talents in a bid to drive the applications of high end aluminium extrusion products.

Mr. Lu concluded, "The Chinese government has put forward a number of policies to upgrade the industry in “12th Five-Year Development Plan for Nonferrous Metals Industry (2011-2015)”, thereby encouraging the application of high performance aluminium alloy and making positive efforts to move the manufacturing industry towards the high-end. Following rising urbanization in China, the development of high-end aluminium products will be more diversified, offering bright prospects for the Group’s aluminium business. In future, the Group will remain committed to its three core business strategies, expanding domestic and overseas client base, strengthening technological innovation and optimizing product mix, with a view to enhancing operating results and creating values for our shareholders.”