China Zhongwang set up its first technology centre in 1998, and has since made continuous investment to stay at the industry forefront. Last year, it invested approximately RMB500 million on R&D on a full-year basis. At present, China Zhongwang has a number of designated R&D units including a national-level enterprise technology centre, a state-local collaborated research centre, a national-level post-doctoral workstation, a provincial engineering and technology research centre, as well as a key laboratory. These establishments undertake a number of national, provincial, municipal, and regional science and technology projects.The Group was awarded a total of 712 licensed patents.In addition, the Group cooperates with leading industry research institutions. This enables the Group to elevate the level of scientific research and effectively expand downstream applications of aluminium products. In 2013, China Zhongwang was listed as a "National High-tech Enterprise".

China Zhongwang has 3,830 R&D and quality control professionals, accounting for 10.1% of the Group’s total headcount. These pioneering personnel specialise in the R&D, design and testing of new processes, technologies, materials, and equipment of aluminium and its alloy, while overseeing the Group’s entire production chain. By establishing a top-tier industrial design team to provide integrated solutions such as product design and production services, the Group has been able to capture the opportunities brought about by the growing light-weight development. Not only does the Group fully leverage its own advantages, but it also cooperates with universities and research institutions, to create a source for an endless stream of talent and innovative technology to achieve breakthroughs in high-end product development.

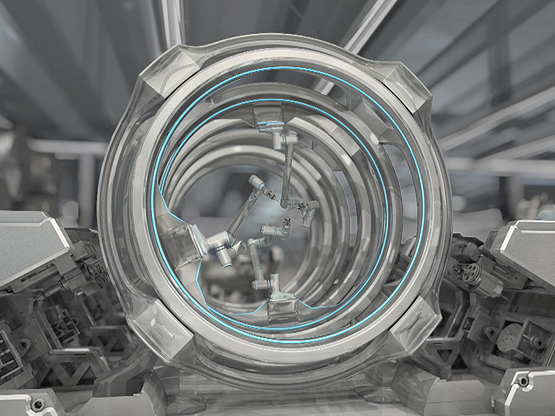

China Zhongwang possesses and utilises leading-edge equipment to reinforce its competitiveness. The Group owns the most number of large-scale aluminium extrusion equipment in the world. It has more than 100 aluminium extrusion lines (including 23 production lines of large-scale aluminium extrusion presses of 75MN or above), and two of the largest and most up-to-date ultra-large 225MN extrusion presses. In 2016, the Group ordered 99 additional extrusion presses, which will be put into operation in the next two to three years. Additionally, China Zhongwang employs innovative smelting and casting equipment from the United States, Canada, and Germany. Armed with cutting-edge equipment for deep processing and related ancillary, the Group operates Asia's largest special industrial aluminium extrusion die design and manufacturing centre. The Group has also been investing in a flat rolling project in Tianjin to build a top-level smart production base. Upon completion, the Tianjin project will become the world’s most advanced production facility with state-of-the-art equipment.

Befitting our dedication to research and development, our innovative mindset, cutting-edge technology, and over 20 years of experience in the industry, the Group has obtained international accreditations in a number of industries including railway, automotive, shipbuilding, and aviation. Such qualifications include the DNV certification, the IRIS certification, the TS16949 Automotive Industry Quality Management System Certification, the AS9100 Aerospace Quality Management System Certification, and the CE Certification by the European Union.

China Zhongwang is a strategic supplier of aluminium alloy profiles for CRRC’s subsidiaries, providing aluminium extruded products used for the body frames of high-speed rail and urban rails. It has also established in-depth collaborative relationships with a number of new-energy vehicle and bus manufacturers, including Volvo, Chery, BYD, Great Wall Arima, Brilliance Auto, FAW, Yutong, and Huanghai, to jointly develop new-energy aluminium-intensive electric vehicles and buses.