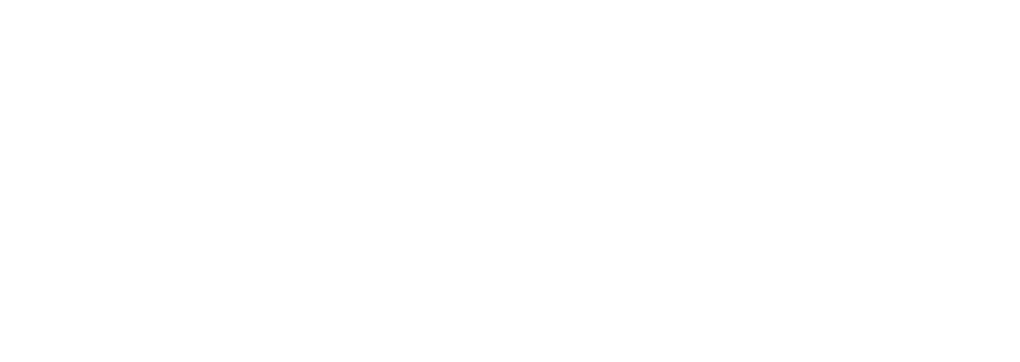

Every gram counts when trying to reduce structural weight in the aerospace and aviation industry, which has become an important field for the application of aluminium. High-strength aluminium alloy has been widely used in plates, extrusion, hulls, and other components in the aerospace industry due to the material’s low density, high-strength, and good thermal durability properties.

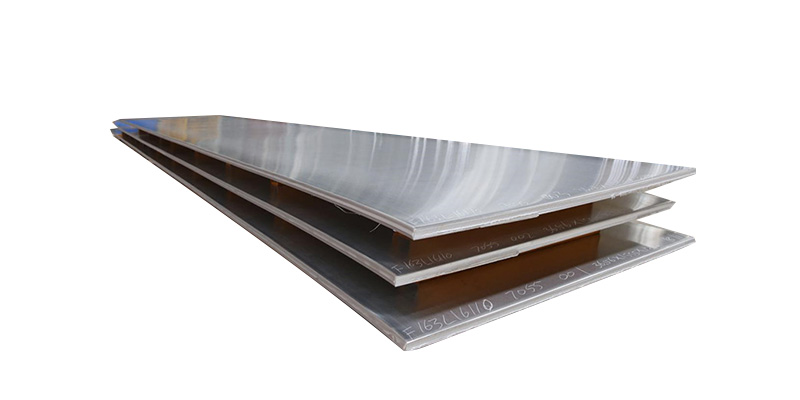

Zhongwang Group manufactures high-strength aluminium alloy plates, sheets, billets, and pipes for aircraft parts and has developed a variety of aviation-dedicated aluminium extruded products such as angled profiles, T-shaped profiles, groove-shaped profiles, Z-shaped profiles, and I-shaped profiles. Looking ahead, the Group will produce large-size, high-performance aerospace plates with high strength, durability, and damage tolerance, to meet the demand of the aviation industry for optimum-quality and high-precision fabricated aluminium products.

Aluminiumwerk Unna AG. (Alunna), a high-end aluminium extrusion subsidiary of China Zhongwang based in Germany, has been in operation for more than a century. Alunna manufactures a myriad of high value-added aluminium alloy extruded products including seamless extruded and porthole extruded tubes. Being one of the three aluminium tube manufacturers with full set of licenses from the aerospace industry, Alunna holds certificates from the top aircraft manufacturers including Airbus, Boeing, Bombardier, BAE Systems, Gulfstream Aerospace Corporation and so on.