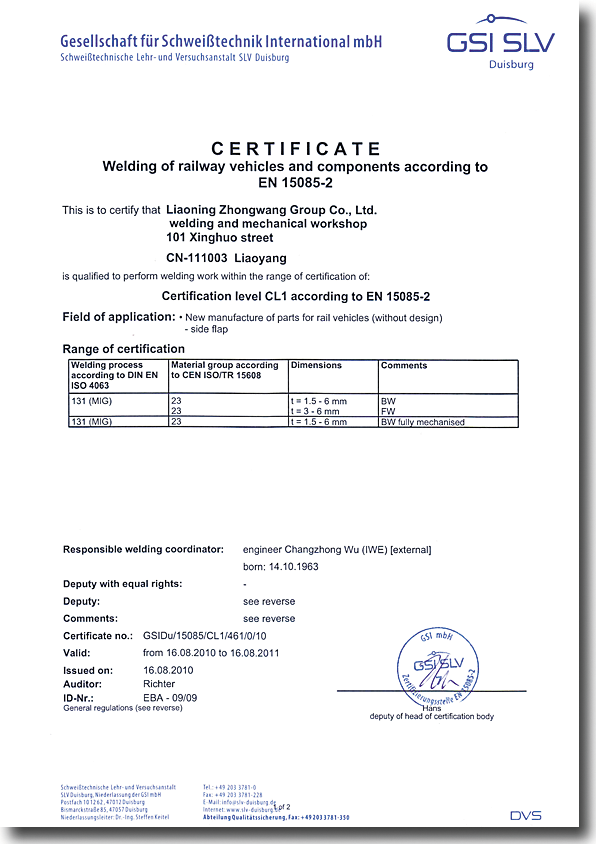

On 16 August 2010, China Zhongwang obtained the EN 15085-2 CL1 certification for its development in the processing of aluminum materials used in railway vehicles and component welding.

EN15085, the standard for “Railway applications-Welding of railway vehicles and components”, is common in the railway industry designed for railway vehicles and vehicle parts and states requirements for product design, production, quality, check-up, testing and identification. The standard applies to the welding of metals (e.g. aluminum alloy, steel, copper and magnesium) for use in the manufacturing and maintenance of railway vehicles as well as components, and is implemented in more than 30 countries across Europe. Therefore, obtaining the certification is a prerequisite for exporting railway vehicles and components to the region.

The EN 15085-2 CL1 certification mainly covers the welding of large components of railway vehicles such as skirts. China Zhongwang introduced advanced technology and facilities two years ago for its aluminum deep processing projects and achieved excellent results, increasing the group’s overall competitiveness in high value-added products and facilitating its obtainment of the EN 15085-2 CL1 certification.

The certification helps China Zhongwang expand into more markets in aluminum deep processing, taking opportunities and laying a foundation for the group’s sales of deep processed products in Europe and other parts of the world.