China Zhongwang 2013 net profit grows 17.7% to RMB2.13 billion

* * *

Proposed dividend HK$0.13 per share, dividend yield at 5.6%

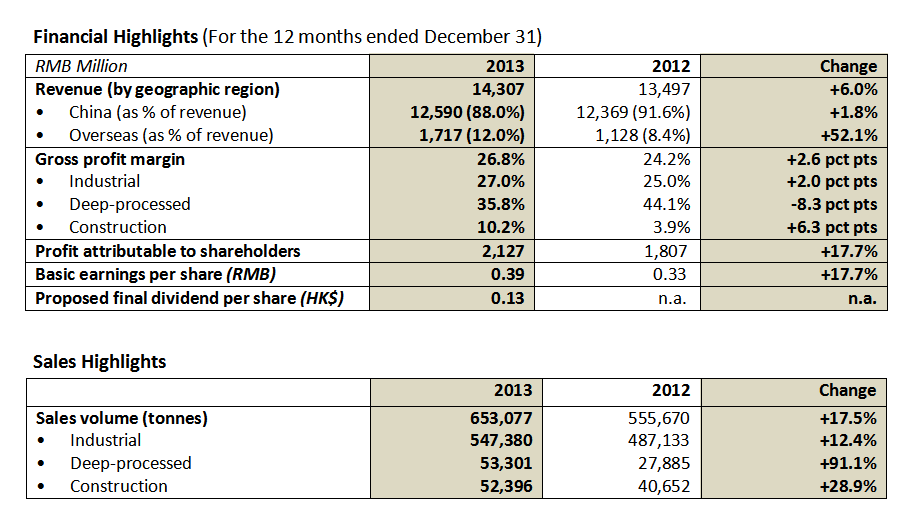

(Hong Kong, 27 March 2014) – China Zhongwang Holdings Limited (“China Zhongwang” or “the Company”, together with its subsidiaries “the Group”, stock code: 01333), the second largest industrial aluminium extrusion product developer and manufacturer in the world and the biggest one in Asia and China, announced the audited annual results for the 12 months ended 31 December 2013. Revenue and profit attributable to equity shareholders amounted to approximately RMB14.31 billion and RMB2.13 billion, representing year-on-year growth of 6.0% and 17.7% respectively. Gross profit margin increased by 2.6 percentage points to 26.8% year-on-year. Earnings per share was up by 17.7% to RMB0.39.

To reward shareholders’ longstanding support for the Company, the board of directors has proposed a final dividend of HK$0.13 (approximately RMB0.10) per share to the holders of ordinary shares and convertible preference shares, or approximately RMB723.7 million in total based on the number of ordinary shares and convertible preference shares as at the date of the announcement of the Group’s annual results. Dividend yield reaches 5.6% based on the closing price of HK$2.32 per share as at 26 March 2014.

Mr. Lu Changqing, Executive Director and Vice President of China Zhongwang, said, “The Group made solid progress in market expansion, product development, technology research, and expansion within the industry chain during the year under review. We are pleased to see sustained stable growth in operating results, thanks to economies of scale generated from the expansion of our production capacity for industrial aluminium extrusion products, higher sales order resulting from dedicated efforts to expand the PRC market, and the new revenue stream generated by the deep-processing centre for industrial aluminium extrusion products which was put online during the year.”

During the year under review, sales volume of aluminium extrusion products rose 17.5% year-on-year to approximately 653,000 tonnes. High value-added industrial aluminium deep-processed products boosted the export business, resulting in a 96.5% growth in export sales volume to approximately 62,000 tonnes, and a 52.1% rise in sales revenue to approximately RMB1.72 billion. Export sales accounted for 12.0% (2012: 8.4%) of the Group’s total sales.

Industrial aluminium extrusion products – world advanced production facilities drive capacity and sales volume growth

Capacity expansion and upgrades play an important role in the Group’s development. During the year, sales volume of industrial aluminium extrusion products increased by 12.4% year-on-year, to approximately 547,000 tonnes, following the completion of installation and testing of eight large-tonnage aluminium extrusion presses. As at the end of 2013, the Group had 93 extrusion lines, including 21 large-tonnage extrusion presses of 75MN or above, among which four were 125MN presses, and a production capacity of over 1 million tonnes.

The Group has also purchased two sets of the world’s most advanced 225MN horizontal single-action aluminium extrusion presses, which will gradually commence operation in 2015 according to the plan. These facilities will enhance the quality and production efficiency of large-section industrial aluminium extrusion products and allow the Group to enjoy higher economies of scale.

Deep-processing business – sales volume surged 91.1% year-on-year to around 53,000 tonnes

During the year under review, sales volume of industrial aluminium extrusion deep-processed products surged 91.1% year-on-year to 53,000 tonnes, while sales value grew 52.9% to RMB1.47 billion. As the new deep-processing centre commenced production during 2013, the Group has developed a series of new products in tandem with the light-weight development in the transportation industry. New prototypes such as aluminium fire vehicles, refuse trucks, high-speed train compartment bodies suitable for alpine cold regions, and semi-trailers were developed. The deep-processed products are more technically advanced and therefore command higher selling prices and gross profit than industrial aluminium extrusion products. The development of the deep-processing business will not only foster a new niche for profit growth, but also further sharpen the Group’s technological level and competitive edge.

Aluminum flat rolled products – scheduled to commence operation in 2015

The Group’s aluminum flat rolled product project saw further development as planned during the year under review. Equipment for aluminum flat rolled products imported from Germany, the United States and other countries will be delivered and installed in different stages in 2014. Phase I of the project with an annual production capacity of 1.8 million tonnes is scheduled for gradual commencement of operation in 2015. Aggregate annual capacity will be increased to 3 million tonnes when Phase II is completed in 2018.

“The aluminum flat rolled project is the largest single-project investment ever in the history of China Zhongwang. It will form a major growth driver of the Group. Located in Wuqing District, Tianjin, it will become, upon completion of construction, an aluminium flat rolled product manufacturing base with the world’s most advanced flat rolling equipment and most comprehensive set of ancillary facilities. The Group plans to offer high value-added aluminium sheet, plate and foil products for industrial sectors with stringent technological requirements, such as aviation and aerospace, rail transportation, automobiles, food and pharmaceutical packaging, chemical containers and engineering equipment,” Mr. Lu added.

Technological innovation – granted preferential tax treatment for three years from 2013

The Group continued to increase its investment in research and development. During the year under review, the Group’s research and development expenditure reached RMB430 million, or 3% of revenue. Three research projects were selected for inclusion, respectively, in the national advanced technology research and development programme (the “863 Programme”), the list of national strategic innovative product projects, and the foundation enhancement project for industrial transformation and upgrade. The Group also received multiple awards for technological progress and innovation at municipal, provincial and national levels, as well as the granting of more than 30 patents.

In November 2013, Liaoning Zhongwang Group Company Limited, the main operating entity of the Group in China, was recognized as a “High & New Technology Enterprise”, entitling it to the enjoyment of a preferential policy on corporate income tax for three years from 2013, during which period the applicable corporate income tax rate will be reduced from 25% to 15%.

“Aluminium is regarded as an effective metal for facilitating light-weight development in transportation. Increasing usage of aluminium for the transportation sector can effectively reduce gas emission of automobiles and help ease widespread smog pollution in China. The Group has been actively advancing the aluminium flat rolled product business, a project that not only conforms to the light-weight development trend in the transportation sector, but also helps make up for China’s lack of production capacity for such high-end products like medium-to-high thickness aluminium alloy plate. Looking ahead, in line with its call for the optimization of industrial structures, China’s “12th Five Year Plan” supports faster applications of new technology, materials and equipment by enterprises, with a view to enhancing their market competitiveness. Greeted by the opportunities arising from environmental protection and economic transformation, China Zhongwang will continue to develop its business in industrial aluminium extrusion products, which will be complemented by high value-added deep-processed products for a more diverse range of product supply. We will also make strategic inroads in aluminum flat rolled products. As we steadily advance the development of our three principal businesses, we will strive to enhance our operating efficiency and governance to enable us to become one of the world’s leading aluminium processing enterprises, creating greater value for our shareholders,” Mr. Lu concluded.