Results Highlights:

• Both revenue and net profit hit a record high in light of the ceaseless product mix optimisation and enhanced added value.

• The contribution of high-end products used in ecological construction, all-aluminium vehicles and railway vehicles increased.

• Client-oriented service model further strengthened with well-developed integrated light-weight solutions.

• Recommended a final dividend of HKD0.17 per share. The dividend per share for the year totalled HKD0.27, equivalent to a dividend payout ratio of approximately 39.2%.

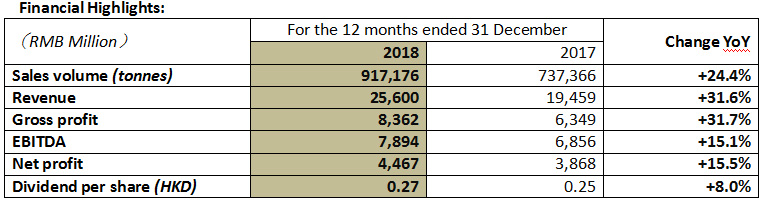

(Hong Kong, 29 March 2019) - China Zhongwang Holdings Limited (“China Zhongwang” or the “Company”, together with its subsidiaries the “Group”, stock code: 01333), a world-leading fabricated aluminium products developer and manufacturer, announced its audited results for the year ended 31 December 2018 (“the Year under Review”). During the Year under Review, the sales of high-end products such as aluminium alloy formwork and large-sized parts for railway vehicles achieved satisfactory results, coupled with stable contribution from the flat rolling business, the total sales volume of the Group increased by 24.4% year-on-year to 917,176 tonnes. In light of the continuing product mix optimisation and enhanced added value, the Group’s total revenue rose by 31.6% year-on-year to RMB25.6 billion. Overall gross profit up by 31.7% year-on-year to RMB8.4 billion. Gross margin was 32.7%. Net profit up by 15.5% year-on-year to RMB4.5 billion.

The Board has recommended a final dividend of HKD0.17 per share. Together with the interim dividend of HKD0.10 per share, the dividend per share for the year totalled HKD0.27, equivalent to a dividend payout ratio of approximately 39.2% on a full-year basis.

Mr. Lu Changqing, Chairman and President of China Zhongwang, said, “China’s economy has shifted to a high-quality development stage with stable growth, fostering sustainable development of various industries, thereby bringing forth exciting opportunities for the eco-friendly material aluminium alloy. Riding on our strong research and development strengths, the Group has strived to achieve differentiated advantages in respect of its product mix, business footprint and service model, providing integrated light-weight solutions to high-end sectors such as ecological construction, new energy vehicles and rail transportation. Hard work pays off, the Group achieved satisfactory results in 2018.”

Aluminium Extrusion Business – Leading Ecological Construction Solution with Unremitting Product Upgrade

Being a new ecological construction material, aluminium alloy formwork has become a key product of the Group in recent years. The product has obtained 18 patents with a nationwide clientele since its launch. During the Year under Review, the aluminium alloy formwork continued to be the growth engine of the Group’s overall performance. In addition to continuously improving product quality and environmental performance, the Group has developed a 3D modelling technology to shorten the design and production lead time. The Group was honoured as “The Most Influential Supplier in the National Aluminium Alloy Formwork Industry 2018”, an industry recognition on the Group’s leading position. Never settle for less, the Group has been developing the all-aluminium formwork components and scaffoldings, leading the innovative application of the product.

Further Fabrication Business – Capitalise on Light-weight Development of Transportation with One-stop Integrated Services

The Group achieved steady growth in further fabrication business as it focused on the high value-added products including large-sized parts for rail vehicles, all-aluminium body frames and parts for passenger vehicles. Leveraging the capability of offering one-stop solutions, the Group has provided light-weight solutions to a number of automakers such as CH-Auto Technology, Chery New Energy, and FAW Group. The Group was awarded as an “Outstanding Supplier 2018” by Chery Automobile. Being a key supplier of further fabricated aluminium products for the high-speed train “Fuxing EMU” and an exclusive supplier of large-sized further fabricated aluminium parts for the commercial maglev 2.0 trains, the Group has unceasingly contributed to the upgrade of China’s rail transportation. In view of the change in client mix, the Group has been strategically expanding its production bases nationwide to provide all-round services spanning R&D, production and after-sales services to the customers. In particular, the Wuhu plant designated for the new energy vehicles has gradually commenced production during the Year under Review.

Flat Rolling Business – Push Forward High-End Production Qualifications to Optimise Business Layout

In response to the increasingly diverse market demands, the Group has been actively pushing forward the aluminium flat rolling project in Tianjin. The first production line has been contributing stable revenue to the Group with improved efficiency. The project has obtained a series of authoritative production qualifications covering a wide range of sectors, including aviation, shipbuilding, rail transportation and automotive. The aluminium automotive body sheet has passed accreditations from a number of new energy vehicle OEMs in China, and pilot production is underway. Meanwhile, the second production line has been conducting trial production for potential clients.

Further Extension of Industry Chain Through Prudent Global Expansion

Deeply rooted in the China market, the Group is also aiming at exploring market opportunities abroad. During the Year under Review, The Group became a Tier-1 supplier to Jaguar Land Rover and will provide quality aluminium alloy product solutions to its British plant, marking the Group’s first foray into the supply chain of overseas automakers. Alunna, the Group’s high-end aluminium extrusion subsidiary in Germany, has enhanced production efficiency significantly. Notably, Alunna passed the Airbus IPCA-Plus-Audit and achieved an excellent level “A” rating. In addition, the Group’s all-aluminium superyacht builder Silver Yachts will deliver a newly-built luxury superyacht in 2019. Silver Yachts has tapped into China market by establishing a shipyard in Jiangmen, Guangdong Province in China to manufacture all-aluminium yachts and commercial vessels.

Looking ahead, Mr. Lu concluded, “Government Work Report 2019 has laid out numerous positive measures to create a favourable business environment for the private sector. As one of the leading private enterprises in China, China Zhongwang will continue to foster the entrepreneurship, and promote the application of the ecological aluminium alloy with relentless technological innovation. 2019 marks the 10th anniversary of the listing of China Zhongwang on the Hong Kong Stock Exchange. On behalf of the Board, I would like to extend our appreciation to all the colleagues, our shareholders, customers and business partners for their support and trust all along. China Zhongwang will remain committed to its mission and shoulder its responsibilities, and lead the upgrade and transformation of the aluminium fabrication industry, bringing integrated light-weight solutions to the society. ”