Results Highlights:

• A double-digit increase achieved in sales volume and revenue, steady growth in net profit

• Developing all-aluminium formwork components, and initiating the leasing business of aluminium alloy formwork

• Client-oriented strategy for the support of new energy vehicles and fabricated products

• High-end products continue to contribute, including the delivery of a newly-built all-aluminium superyacht by Silver Yachts

• An interim dividend of HK$0.1 per share declared, representing a dividend payout ratio of approximately 45.9%

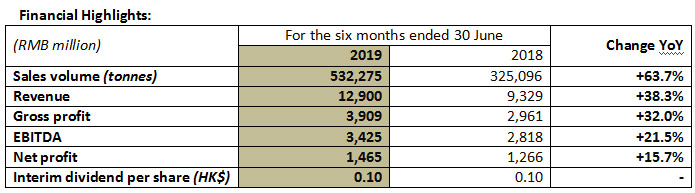

(Hong Kong, 23 August 2019) - China Zhongwang Holdings Limited (“China Zhongwang” or the “Company”, which together with its subsidiaries is referred to as the “Group”, stock code: 01333), a leading developer and manufacturer of fabricated aluminium products in the world, announced its unaudited results for the six months ended 30 June 2019 (“the Period under Review”). During the Period under Review, the demand for high-quality aluminium products increased, contributing to sharp increases in the sales of the Group’s industrial extruded aluminium products and aluminium flat-rolled products. Such, coupled with the encouraging sales performance of the aluminium alloy formwork, drove up the Group’s overall sales volume by 63.7% year on year to 532,275 tonnes. As a result, the Group’s total revenue rose by 38.3% year on year to RMB12.90 billion. Gross profit grew by 32% year on year to RMB3.91 billion. Gross margin amounted to 30.3%. Net profit increased by 15.7% year on year to RMB1.47 billion.

The Board has declared an interim dividend of HK$0.1 per share, which represents a dividend payout ratio of approximately 45.9%.

Mr. Lu Changqing, Chairman and President of China Zhongwang, said, “On the back of the ongoing upgrading and transformation of China’s manufacturing industry, breakthroughs are being made in widening the applications of aluminium alloy, which is dubbed a ‘green metal’, in various industries. The Group’s outstanding capability in research and development, specialisation in high-end products and consistent optimisation of its product mix have enabled it to progressively expand its businesses, providing one-stop light-weight solutions for such high-end applications as ecological construction, new energy vehicles, rail transport, shipbuilding and aviation. The Group always dedicates itself to the aluminium fabrication, therefore it has long been in a leading position in the industry.”

Aluminium Extrusion Business - Initiating the leasing business of aluminium alloy formwork with the aim of enhancing long-term profitability

Aluminium alloy formwork has been widely used as an ecological building material in recent years. During the Period under Review, the aluminium alloy formwork continued to contribute to the Group's financial results. With its expertise in design, techniques and technology, the Group successfully developed a comprehensive range of aluminium formwork system that include aluminium supporting components and connectors, enriching its product mix. Meanwhile, the application of aluminium alloy formwork has been extended to infrastructure construction, such as underground integrated pipe corridors, subway tunnels and airport tunnels, thus increased the penetration rate of aluminium alloy formwork.

To ensure its sustainable development, and enhance its long-term profitability, the Group commenced the leasing business of aluminium alloy formwork. This not only deepens the Group’s contact with the end market but may also widen its potential profit in the long run.

Aluminium Flat Rolling Business – Pressing ahead with capacity ramp-up and effort to obtain certification for high-end products to align with international standards

The Group has been making progress at its aluminium flat rolling plant in Tianjin in response to the demand for high-end aluminium products. The first production line has been running smoothly and fully integrated with improved production efficiency, unlocking the production capacity. During the Period under Review, sales volume at the Group’s aluminium flat rolling plant increased significantly. The clients of the flat rolling business are mainly from the industrial and transportation sector, the Group is also supplying in small amount of automotive body sheets for new energy vehicle manufacturers. Meanwhile, the Group has been working on product accreditation procedures with some European brands and Japanese brands. It has also developed a wide range of aluminium products for packaging, including aluminium alloy sheets for can lids, laptop casings and soft-pack battery. The second production line at the plant in Tianjin has commenced pilot production in small scale.

Further Fabrication Business – Pursuing excellence in the business of producing value-added products and leading the industry in the development of light-weight solution for the transportation sector

To capitalise on the growing trend towards a light-weight solution in the transportation sector, the Group actively research on and develop various high value-added products that can be used in passenger cars, buses, urban logistics vehicles and rail transit vehicles. This can lead to steady growth in its further fabrication business. The Group’s technologies for producing all-aluminium body and chassis of new energy vehicles have reached the international advanced level. Such technologies are expected to be widely used in various fields, including high-speed trains, subway carriages and the new energy vehicles. As a major supplier of aluminium parts for “Fuxing EMU” high-speed train bodies, the Group contributes to the upgrading of China’s railway system by providing various types of further fabricated aluminium products.

Expanding business globally in a prudent and successive approach

The Group stays committed to its strategy of “focusing primarily on the China market and to a lesser extent on the overseas markets”, and plans carefully for its global expansion. The advantage in experience and technology of the Group’s overseas operations has been reflected in the results performance. Alunna, a high-end aluminium extrusion subsidiary based in Germany, continued to contribute steadily to the Group’s profit. Silver Yachts, an aluminium alloy superyacht builder based in Australia, delivered a newly-built luxury superyacht. In China, the Group has completed setup its shipyard in Jiangmen to manufacture all-aluminium yachts and commercial vessels, production of the first all-aluminium yacht is in progress.

Looking ahead, Mr. Lu concluded, “The year 2019 marks the 10th anniversary of China Zhongwang’s listing on the Hong Kong Stock Exchange. Over the past decade, the Group has always upheld its core values and became a reliable partner for our customers. As aluminium find its potential in different applications, the Group will continue its effort in aluminium fabrication with its leading integrated light-weight solutions, awaiting to be inspired by more aspirations and enlightenment.”